Naziv vsebine

EPOFORM 100 1000 + 500 g

ADVANTAGES

- Long working time

- High strength and toughness

- Pigmentable with dry VIVAT, EFFECT pigments

- Precisely machinable cured surface

- Adaptable hardness and weight with K5, Mikrosil, Talc CL-40, Baryte fillers

PROPERTIES

Mixing ratio: 100:50 by weight

Pot life (150 g, 20°C): 30-60 minutes

Cure time: 24 hours

USE:

Weigh components A and B in a 100:50 ratio and mix thoroughly. Pour the mass into another container and mix again. Apply to the surface of the foam, wood, etc., and smooth the surface with a spatula or a brush.

LOWER DENSITY / EXPANDED VOLUME: Add MIKROSIL (approximately 1-10% of the EPOFORM-100 weight)

ENHANCED HARDNESS: Add K-5 Filler or TALCUM (20 – 80 %)

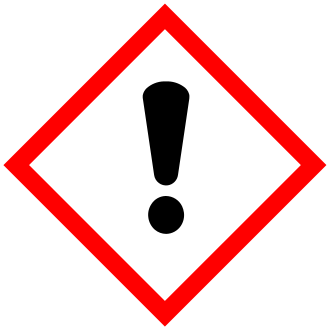

DANGEROUS

H315 Causes skin irritation.

H319 Causes severe eye irritation.

H317 May cause an allergic skin reaction.

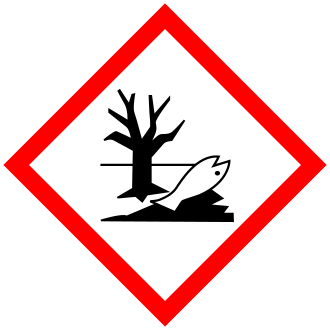

H411 Toxic to aquatic life with long lasting effects.

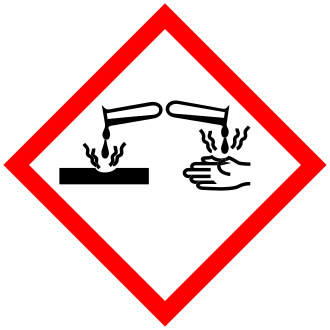

H314 Causes severe skin burns and eye damage.

Sum of harmfulness for fertility. Sum of harmfulness for the unborn child.

P280 Wear protective gloves/protective clothing/eye protection/face protection.

P305 + P351 + P338 IN CASE OF CONTACT WITH EYES: Rinse cautiously with water for several minutes. Remove contact lenses, if present and easy to do. Continue rinsing.

P310 Immediately call the POISON CENTER/doctor/….

P261 Do not inhale dust/smoke/gas/mist/vapors/aerosols.

P273 Prevent release into the environment.

P333 + P313 If skin irritation occurs or rash appears: seek medical advice/attention.